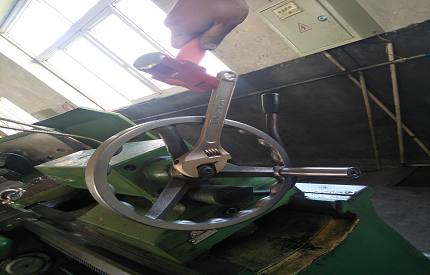

1. According to the actual work needs, select the appropriate specifications of non-sparking tools. For example, the specification of the nut must be standardized, the metric or inch size to distinguish, choose the appropriate wrench, if the selection of the wrench specification is smaller than the nut, of course, it can not use, but the selection of the specification is large, will cause the wrench local point force, popularly speaking, is easy to damage the tool, hurt the nut surface. In addition, the non-standard screw nut, after the long-term use of the worn screw nut, must provide the actual size of the screw nut to us, we will tailor the appropriate wrench for you. During the selection of F wrench type tools, according to the valve specifications, within the allowable range, select a larger specification of the wrench, so that, will not be due to the small horse pull large car, excessive use of the tool damage. operator use, also more rest assured.

Priority choice in the same environment

(larger size F valve wrench)

Try not to choose under the same circumstances

(smaller size F valve wrench)

F type valve wrench comparison

The selected spanner does not match the nut specification

2.For the long-lasting rust bolt nut, for the hydraulic equipment to remove, fasten, semi-permanent corrosion bolt nut, can not be directly operated with non-sparking wrench, must first take measures such as rust removal, lubrication, to prevent damage to the tool, sliding injury.

3.The non-sparking wrenches, is according to the related standard design shape size, is corresponding to the specification, such as the small specification wrench L length to be relatively short, the operation is free, if a specification opening size 10 mm spanner, the design L length 500 mm, the operator is easy to remove 10mm wrenches and nuts should be able to bear the torque, resulting in unnecessary waste. This requires that in normal use, not in order to save effort, arbitrary casing, not to use a hammer instead of manpower, hit the wrench except the striking wrenches.

Never allow casing to be used

Never allow a hammer to hit adjustable wrench (not striking wrench)

4.When the non-sparking tool is reused, it should be checked carefully. For example, hammer, check the damage degree of hammer head, whether the hammer handle is loose; non-sparking chain hoist and other lifting tools, according to the use instructions to check for the re-loading use; check the surface of non-sparking tools and the object is clean or not, to avoid the surface of the attachment impact, and the third party impact sparks.

The handle of the hammer has been loosened, stop using.

The hammer head is badly damaged, it is recommended to replace new one.

5.Cutting edge tools, such as scissors, pliers, flat chisels, before the selection, must be clear the hardness of the workpiece, such as higher than the hardness of non-sparking tools, must not be used. Avoid cutting edge of tools breakage and crack. Before selecting and using tools, be sure to understand the scope of use of the non-sparking tools, our product catalogue is marked, if there is any uncertainty, you can communicate with our sales manager again.

6.When using a wrench, be sure to pay attention to the direction of force, such as a adjustable wrench, must be forced to the direction of the small mouth part; when the ring wrench or open wrench loose or fastening nut, horizontal placement, contact area as large as possible, to prevent contact part is not enough, upward or downward tilt, damage to wrench caused by improper use.

The wrench is not fully in contact with the nut, the handle is upturned and used improperly.

Wrench contact nut area too small, improper use.

Right direction of force

Wrong direction of force

The wrong direction of use, do not allow external forces.

Properly used methods

Previous: Maintenance of non-sparking tools